WIANNO SENIOR

One-Design Gaff Rigged Sloop.

Beginning as a carved half-hull on the workbench to being lofted on the shop floor, the Wianno Senior has been a popular racer and day sailor since hull #1 was constructed and launched in Osterville over 100 years ago.

The Senior hull is made at an off-site facility and uses a resin-infused construction method which guarantees all hulls are virtually identical. In this first photo the hull is hanging by her lifting point and ready for inspection, the second photo shows the topsides looking fair and the third has the hull passing inspection and transporting her to the shop.

The below images show the care and joinery detail involved with constructing the Senior’s companionway. The rabbetting and biscuiting detail insures an incredibly strong and long-lasting unit.

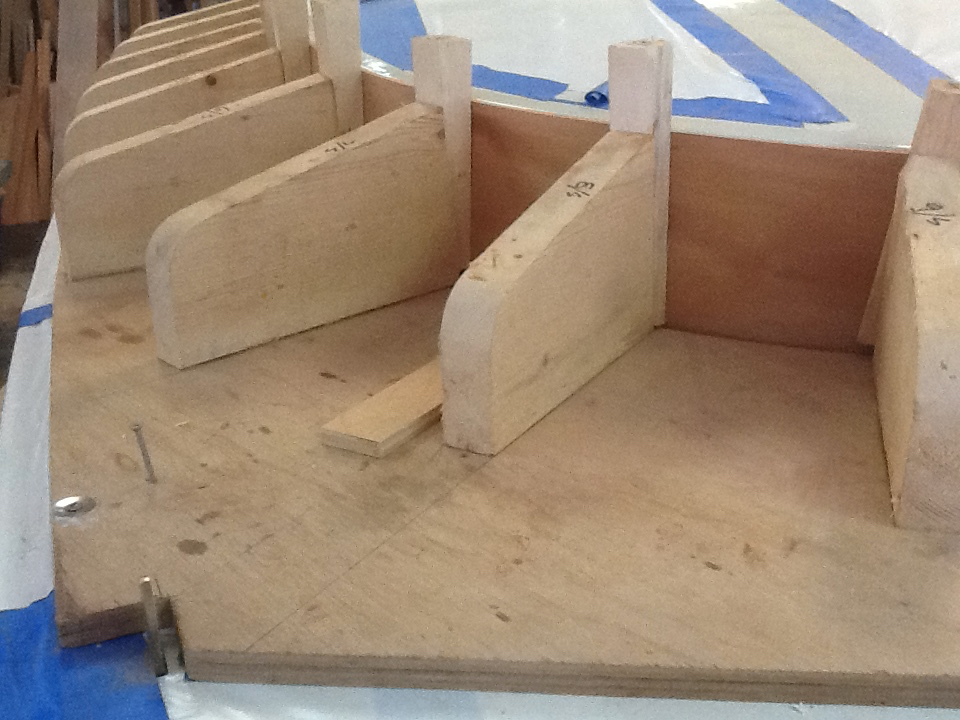

The below images show the coamings being laminated using our extensive network of jigs. These jigs are essential and unique to our construction methods, and allow us to glue the components in place…there are very few fasteners. Each jig is its own entity, consisting of a plywood base that is temporarily fastened in place in areas that will eventually be covered by other trim elements (toe rail, mast partner, etc.).

This piece originally was there to capture and hide the egde of the housetop canvas, that protected the wooden housetop of the traditional boat. This trim is unnecessary now that the sub-structure is fiberglass and without canvas, but it is a critical component of the attractive “look” of the Wianno Senior and makes the fiberglass version virtually identical to her wooden predecessors.

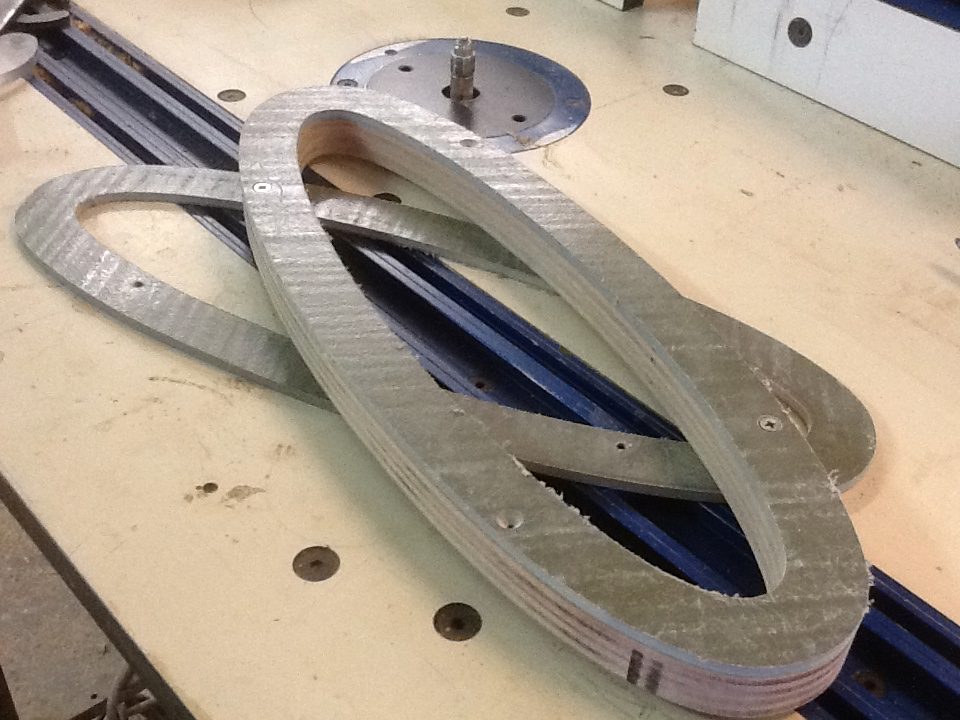

The below images show the mahogany portlight trim rings being routed from the pattern. These trim rings are a departure from the original “puttied” portlights, but represent the evolution of the Wianno Senior details and joinery, thus allowing her to compete with the finest, similar “one-design” fleets.

The below images illustrate our mast construction. It begins with (3) 2” laminates of “aircraft” grade sitka spruce, 26’ long. A tapered pattern is then marked on the four sides and it begins to take shape on the band saw. The four corners of the blank are then power planed off equally, giving the blank eight sides. The remaining corners are hand planed off, resulting in a near round blank…it is then sanded smooth.